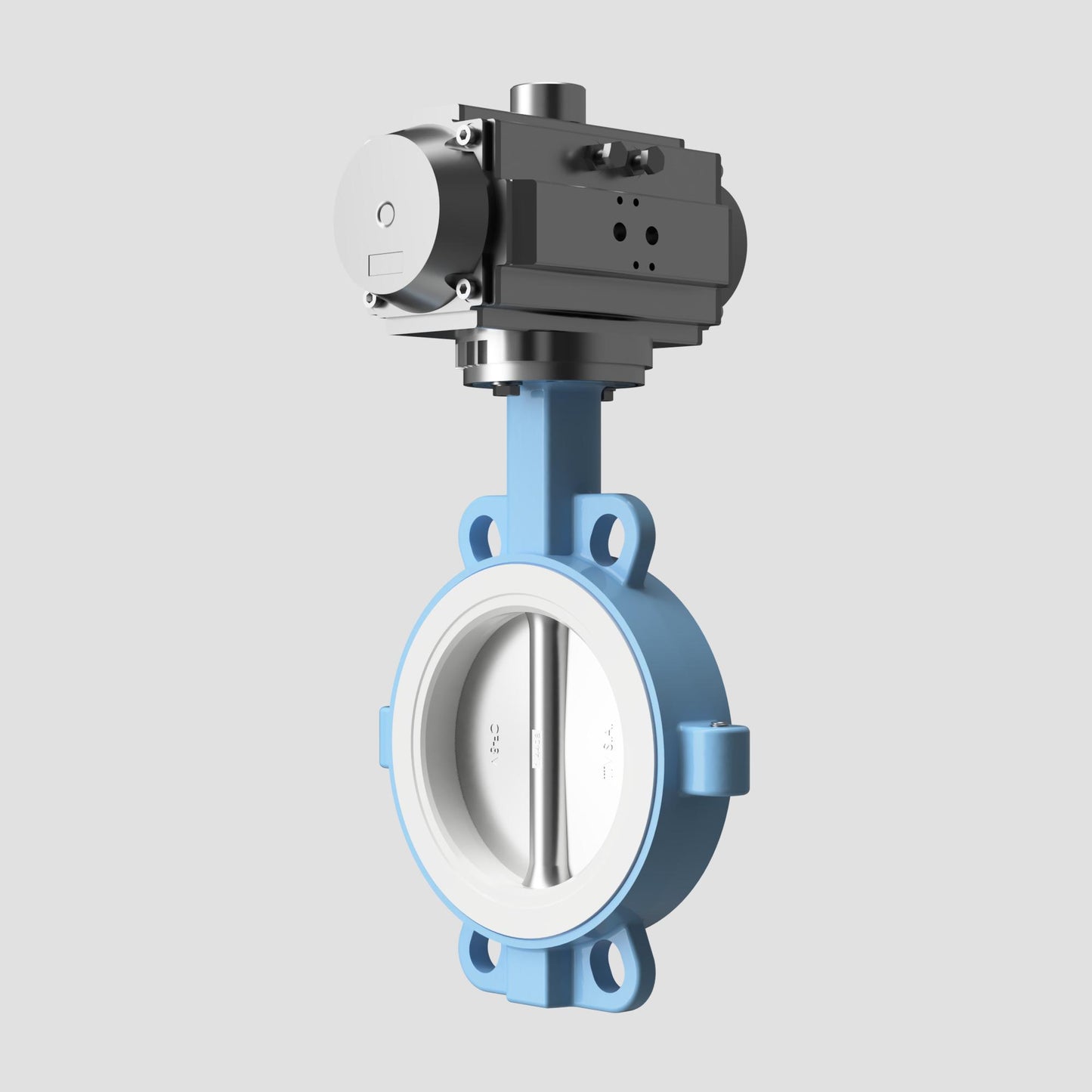

V-Tork Actuated Wafer PTFE Seat Butterfly Valve

V-Tork Actuated Wafer PTFE Seat Butterfly Valve

Couldn't load pickup availability

This actuated valve is a high-performance industrial valve designed for precision control and reliable sealing in a wide range of applications. With a focus on durability and efficiency, this valve integrates advanced materials and automation technology to meet the demands of modern industrial environments, including chemical processing, water treatment, and HVAC systems.

Key Features:

-

Actuation Options: The valve is equipped with a robust actuator, available in pneumatic, electric, or hydraulic versions. These actuators allow for seamless integration into automated systems, enabling remote operation and precise control of the valve position, whether for full open/close operations or modulating control.

-

Wafer Design: The wafer-style body is compact and lightweight, making it easy to install between flanges in piping systems. This design is ideal for applications where space is limited, and it provides a cost-effective solution compared to traditional flanged valves.

-

PTFE Seat: The valve features a PTFE (Polytetrafluoroethylene) seat, known for its excellent chemical resistance and low friction properties. PTFE is inert to most chemicals, making this valve suitable for handling corrosive fluids, while also providing a tight seal and reducing wear over time.

-

Corrosion-Resistant Construction: The body of the valve is typically made from high-quality materials such as stainless steel, carbon steel, or ductile iron, which are treated or coated to resist corrosion. This ensures longevity even in harsh or chemically aggressive environments.

-

Bubble-Tight Shutoff: The combination of the PTFE seat and the precision-machined disc ensures a bubble-tight shutoff, which is crucial for applications where leakage cannot be tolerated, such as in the handling of hazardous chemicals or in critical water supply systems.

-

Bi-Directional Flow: The V-Tork Wafer Butterfly Valve is designed to handle flow in both directions, offering flexibility in system design and installation, and simplifying maintenance and operation.

-

Ease of Installation and Maintenance: The valve's wafer design allows for quick and easy installation between existing flanges without the need for additional hardware. The simple structure also means that maintenance is straightforward, with easy access to internal components when needed.

-

Wide Temperature and Pressure Range: The valve is engineered to operate effectively over a broad range of temperatures and pressures, making it suitable for both high-temperature and low-temperature applications, as well as varying pressure conditions.

-

Compact and Lightweight: The wafer design, combined with the lightweight materials used in construction, results in a valve that is easy to handle and install, reducing labor costs and installation time.

-

Versatile Applications: The V-Tork Actuated Wafer PTFE Seat Butterfly Valve is ideal for use in a variety of industries, including chemical processing, pharmaceuticals, food and beverage, water treatment, HVAC, and more, thanks to its chemical resistance, reliability, and ease of automation.

Technical Specifications:

- Body Material: Carbon Steel, Stainless Steel, or Ductile Iron (depending on application)

- Seat Material: PTFE (Polytetrafluoroethylene)

- Disc Material: Stainless Steel, Coated Carbon Steel, or other corrosion-resistant alloys

- Pressure Rating: Typically up to ANSI Class 150, with other ratings available depending on the configuration

- Temperature Range: -20°C to 180°C (may vary depending on materials used)

- Size Range: Available in a wide range of sizes, typically from 2 inches to 24 inches

- Actuation: Pneumatic, Electric, or Hydraulic

- End Connections: Wafer style, compatible with ANSI, DIN, JIS, and other international flange standards

Applications:

- Chemical Processing: Ideal for handling aggressive chemicals and solvents.

- Water Treatment: Used in filtration, desalination, and distribution systems.

- HVAC Systems: Controls flow in heating, ventilation, and air conditioning systems.

- Food and Beverage: Suitable for applications requiring sanitary conditions and chemical resistance.

- Pharmaceuticals: Used in cleanrooms and processing facilities where contamination must be minimised.

Conclusion:

This valve is a versatile, reliable, and high-performance valve solution for modern industrial applications. Its combination of automation capabilities, chemical resistance, and ease of installation makes it a valuable component in systems requiring precise flow control and durability.

Share